Bush Lane House

1976

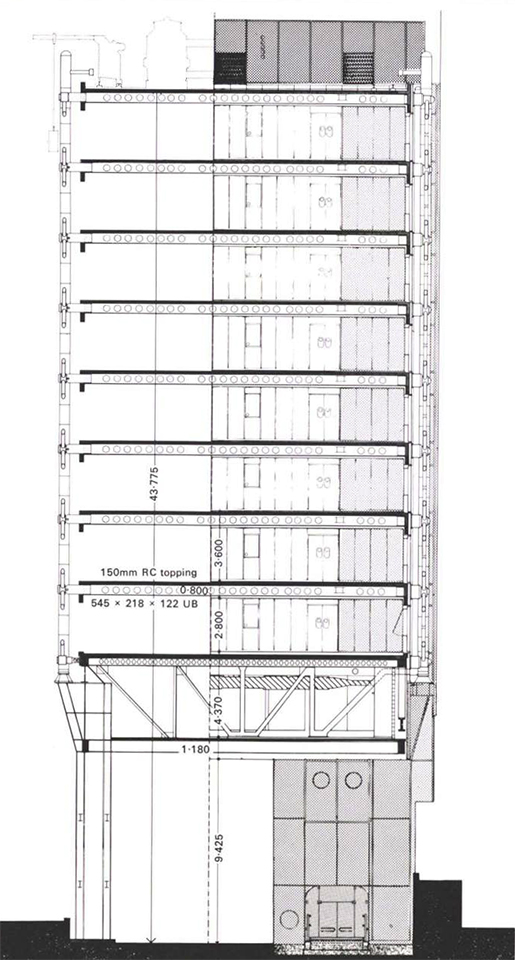

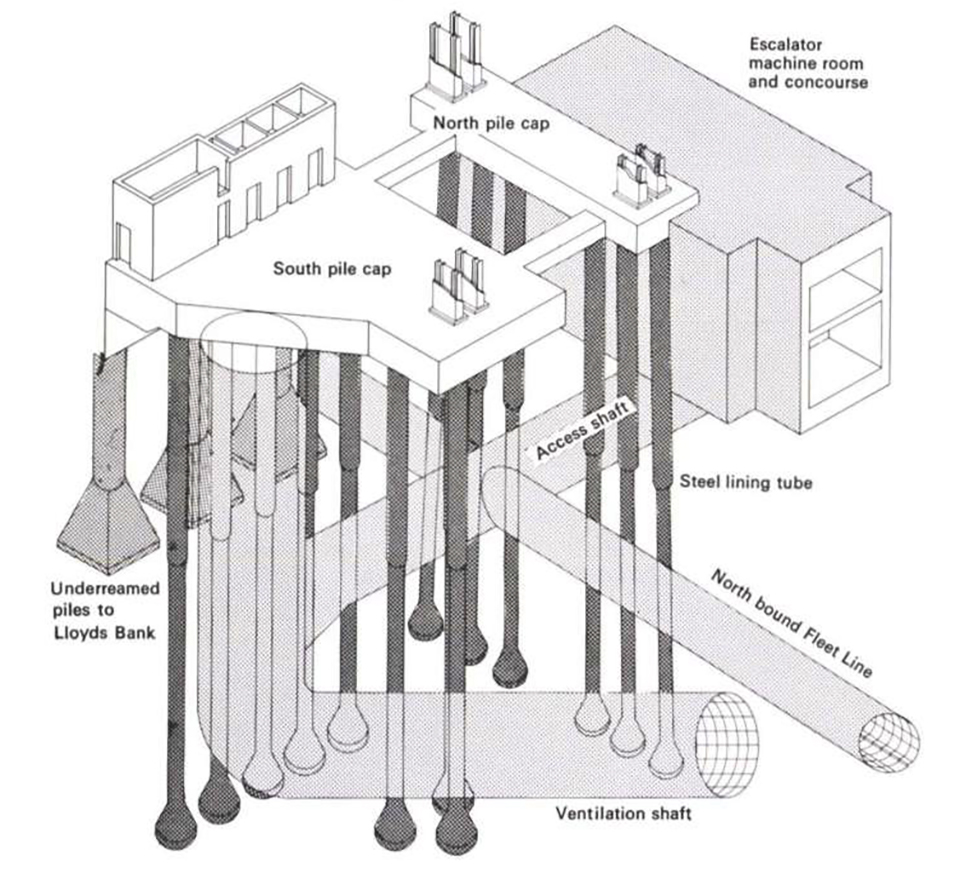

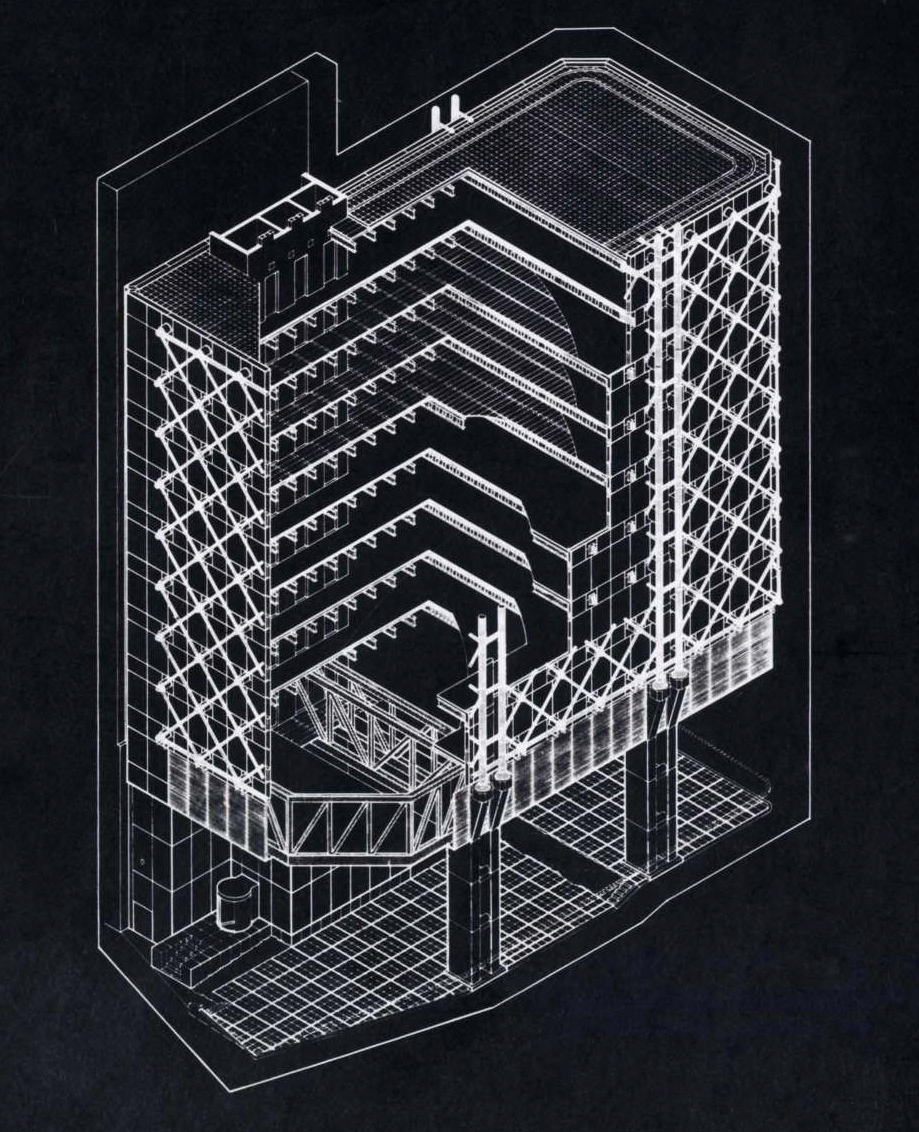

Super-techno is the only phrase suitable to describe this imaginative and innovative office building. The only thing dull are the floor plates, beyond that, the design team had to invent all manner of structural and mechanical solutions to a host of constraints on this inner London Site. The Arup Journal provides a detailed account of its development and construction and makes no apology in this case for their tendency to ‘concentrate attention on the technical aspects of [their] designs’. [1] The foundation solution was subject to all manner of tunnels, easements and access requirements for the underground serving the adjacent Cannon Street Station and the feasibility study for how to overcome just this difficulty formed part of the development deal with London Transport. Three columns and a service core formed the basis for a transfer structure made of trusses that were the full depth of the plant room floor. Unusually, the plant room was on the first floor, 10m above street level to enable maintenance access to the tube. Above the plant room, eight floors of commercial office space were optimised in plan by extending their plates over the pavement line and then cutting chamfers back according to the right to daylight restrictions. The overall height of the building was limited by protected views of St. Paul’s, thus the entire volume was determined by literally pushing the envelope to its limits. This extended to the structural solution for the upper floors – by making a stainless steel exoskeleton, the need for internal columns was avoided and created more flexible, lettable floor space for the developer, City and West End Properties. This in turn presented its own problem, that of fire protection. This was overcome by a pressurised water-cooling system within the core of the exoskeleton itself to give one hour fire protection to the structure. Before the tubes were filled with the potassium carbonate and potassium nitrate solution, the lattice was pressure tested with water containing a fluorescent dye and no leaks were observed. This is testament to the exacting standards of the specification and manufacturing by APV Paramount (casting), Burnet & Rolfe (fabrication) and Boulton & Paul (erection). The signage and wayfinding was done by Pentagram and the overall effect was truly Space Age, arguably hi-tech at its highest technological resolution.

[1] Arup Journal, December 1976, p.6